We Know Success!

Our Team has been successful, they understand the needs of the client and apply them efficiently.

Industrial Projects

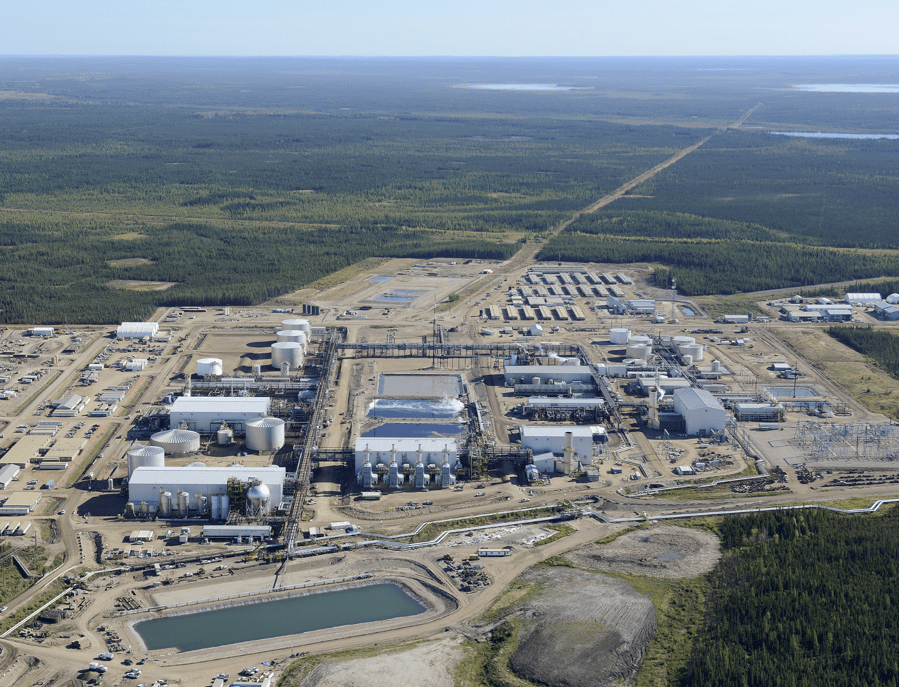

Petro China Canada

Mackay River Oilsands

Mackay River Oilsands is owned and operated by PetroChina Canada. It is located approximately 30 km west of Fort McMurray, Alberta. The projected lifespan is 1.7 billion barrels of bitumen. The daily production is expected to be 150,000 bbls/d. The phase I of the Steam-Assisted Gravity Draining (SAGD) facility is producing 35,000 bbls/d. The first steam was achieved in 2016 and the first Oil production was in Q3 2017.

Encana Cutbank Ridge Program

Near Dawson Creek, British Columbia, Canada

Fluor provided engineering, procurement and construction management services for three similar sweet gas plant projects near Dawson Creek, British Columbia, Canada. The three similar sweet gas plants three projects, Sunrise 04-26, Tower 03-07, and Saturn 15-27 Phase 2, are part of the Cutbank Ridge Partnership Program to develop natural gas and natural gas liquid (NGL) production. The plants will have the capacity to process a combined additional 800 million cubic feet of gas per day. Fluor achieved mechanical completion of the project in November 2017. The project reached mechanical completion in November 2017. Construction of the Sunrise 04-26, Tower 03-07 and Saturn 15-27 facilities was completed safely and with no lost-time incidents in just over two years, ahead of schedule and approximately 10 percent under budget.

ACR-1000

AECL MISSISSAUGA

The Advanced CANDU Reactor-1000 (ACR-1000®1) design is Atomic Energy of Canada Limited’s (AECL) evolutionary, Gen III+, 1200 MWe class pressure tube reactor. It meets the industry and public expectations for safe, reliable, environmentally friendly, low-cost nuclear power generation. It has been designed to be licensable internationally by ensuring its compliance with Canadian nuclear regulations and the fundamental safety objectives of the International Atomic Energy Agency (IAEA) safety standard. The ACR-1000 is a light water cooled, heavy water moderated pressure tube reactor, using low enriched uranium (LEU) fuel with on-power fuelling.

Thompson Concentrate Loadout

Thompson, Manitoba, Canada

Vale Manitoba Operations is currently configured as a fully integrated nickel mining, milling, smelting and refining operation. The operation produces finished electrolytic nickel in several forms at the Thompson Nickel Refinery. These products are used by nickel plating customers throughout the world. Over the course of the last decade several events and studies have resulted in the decision to transition Manitoba Operations to a mining and milling only configuration. This transition must be complete by January 1, 2019, the date on which Manitoba Operations’ emissions Performance Agreement with Environment Canada dictates the Thompson Smelter must be in compliance with the 2015 Base Level Industrial Emissions Regulations (BLIERS). The Thompson Concentrate Load Out Hatch was awarded the contract for Execution Engineering and Project Management support on October 31, 2016. When completed in June 2018, the Project will have constructed the facilities necessary to dewater, truck load and ship a bulk nickel concentrate to customers in Sudbury, or shipped and sold to open market.

Commercial Projects

Sheridan College

Mississauga, On

The new wing offers additional state-of-the-art classrooms, studios, labs and production spaces, a Centre for Creative Thinking, and a gallery space to showcase students’ creativity and innovation.

Square One Shopping

Mississauga, On

Square One is the largest shopping centre in Ontario at 2.2 million square feet, and one of Canada’s top ten malls, Square One is a designated tourist destination and is open on statutory holidays.